Preheating of Fresh Air : Calento SL

Calento SL : Solar Heating of Outside Air

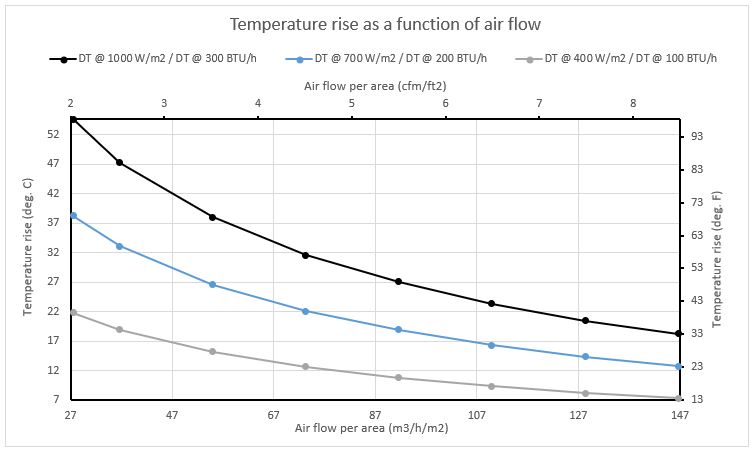

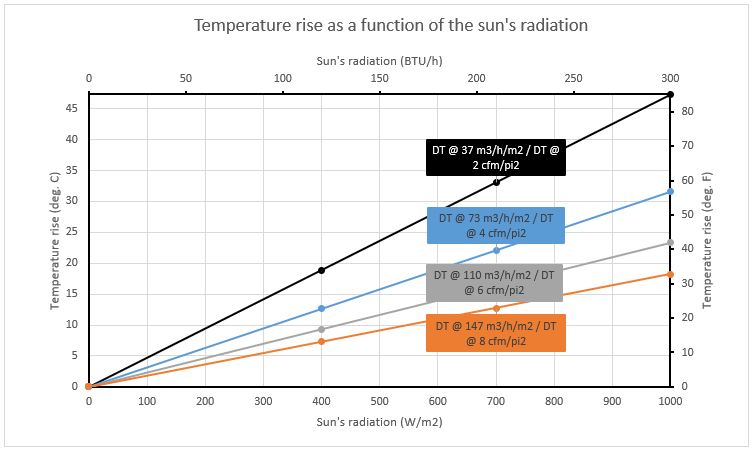

The solar air collector Calento SL uses a surface that has a very low emissivity (3% versus the 95% for black paint) for an optimal heating of the air. Thanks to its certified maximum efficiency of 90.1%*, the Calento SL enables the air to be heated up to a maximum of 50°C above the ambient temperature.

Always being connected to a heating or ventilation system, the Calento SL can be applied to a multitude of HVAC system configurations to generate tangible energy savings, year after year, over several decades.

How the Solar Collector Works

Click Here For Operation with Different HVAC Configurations

Click Here For Cooling with Collectors

Click Here For Collector Manufacturing

Technical Data

Technical Sheet

| Calento SL | SI Units [IP Units] |

|---|---|

| Technical Data | |

| Solar air collector type | transpired, open loop, unglazed |

| Working fluid | air only |

| Main use and purpose | Preheating of outdoor air |

| Peak solar efficiency, rated | 90.1% |

| Maximum power output | 901 W/m2 [285 BTU/hr per ft2] |

| Maximal air throughflow per collector surface | 185 m3/h per m2 [10 pcm/ft2] |

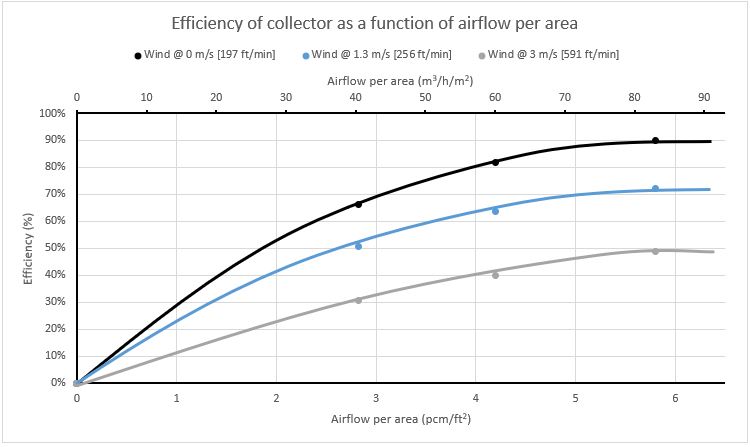

| Pressure drop @ maximum throughflow | 125 Pa [0.5 in H2O] |

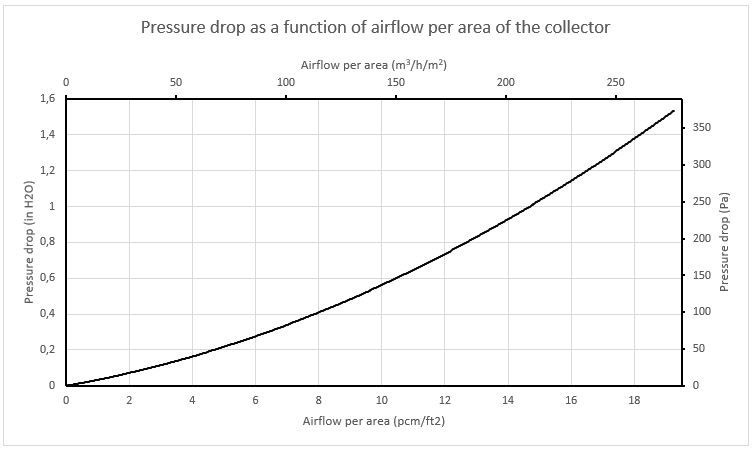

| Maximum temperature rise above ambient | 50 °C [90 °F] |

| RETScreen simulation model performance factor | 1.35 |

| Absorber panel | |

| Panel material | Aluminum alloy 99.8, Temper H18 |

| Absorber panel thickness | 0.7 mm [0.028 in] |

| Panel surface treatment | Highly selective VDP coating |

| Available colors, selective | blue, black |

| Absorbtivity in thermal spectrum | ≥94% |

| Emissivity in thermal spectrum | ≤3% |

| Panel porosity | 1-4% |

| Mounted collector system, on site | |

| Plenum cavity depth, standard | 10 to 20 cm [4 to 8 in] |

| Framing parts, steel | 1.31 mm [18 ga] |

| Weight per surface area, including framing | 5 kg/m2 [2 lbs/ft2] |

| Maintenance requirement | none |

| Freeze protection | unnecessary |

| Overheating protection | unnecessary |

| Ratings & certifications | |

| Solar Rating Certification Corp. certificate no | SRCC 10002111 |

| Solar Keymark certificate no. | 011-7S3104 L |

| Test laboratory | Fraunhofer ISE, Germany |

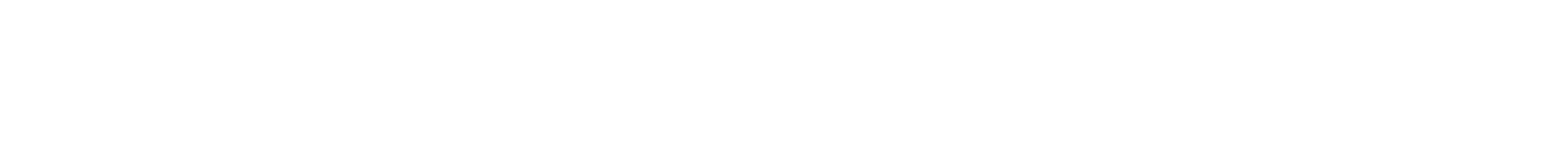

Efficiency Curve of the Solar Collector

Click Here For More Details

Description

Over the years, Trigo has developed a series of surface finishes, perforation patterns and profiles to maximize the thermal output the Calento SL series and answer the most stringent needs of engineers and architects.

For engineers, rated performances allow for a maximum temperature increase of 50°C above ambient, regardless of exterior temperature or time of the year. This enables the integration of the Calento SL in applications like outside air preheating, space heating, heat pump assistance, drying, dessicant wheel regeneration, process heat and any application where warm air is needed.

For architects, selective colors include blue (the natural optical outcome of our vapor deposition process) and black, which was created specifically for building integration. Three different perforation patterns are available, as well as four different standard profiles. For special projects, a further selection of about 20 profiles is available. We exclusively use aluminum as substrate material for its superior thermal conductivity and properties against corrosion, as perforations cause the metal to be exposed.

Installation Videos (In French)

Project Photos